|

|

|

|

|

| From looms to cyclemotors |

|

|

|

| |

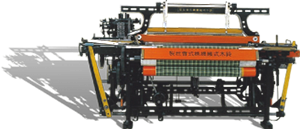

The Suzuki Motor Company is founded by Michio Suzuki, the son of a Japanese cotton farmer. He is born in Hamamatsu in 1887 a small place on 200 km away from Tokyo. When growing up he was a Carpenter and Michio an enterprising young man. In 1909 when he was 22 years old, he designed a by a foot pedal powered wooden loom and he started this as a product to sell. Suzuki Loom Works was founded. The business went well and the order book grew and Michio developed its product on for the silk industry. New more sophisticated looms were developed and the company flourished.

In 1920, eleven years after the founding of the company brings Michio his company to the stock exchange. The company is then entered a new phase and Michio has the capital needed to expand his business to meet the growing market demand. The establishment of Suzuki Loom Manufacturing Company (Suzuki Jidosha Kogyo) in March 1920 is considered to be the start of the Suzuki Motor Company as we know it today. Suzuki Loom Manufacturing Company obtained the necessary capital for the investment and grew quickly. In 1920 it belonged to the largest loom producers of Japan.

|

(foto: Suzuki weefgetouw) |

At that time, Japan was not yet the great industrial power that it is today. The main export products were fabrics and rugs. In 1926 began Suzuki Loom Manufacturing Company with exporting looms to South-East Asia and India. By the excellent quality of the looms, they went almost never piece, began to hit the market saturation and started the demand for new looms. Suzuki started from looking at new products that could be produced in addition to the looms.

In time for the second world war there were in Japan almost no manufacturers of motorcycles and cars. Soichiro Honda would build his first auxiliary engine only in 1947. In Europe and the United States was for decades an engine and car industry. The Otto engine was patented in 1876 in Germany and the "Einspur" the prototype for a motorcycle in 1885 Gottlieb Daimler was already built. Robert Bosch introduced the magnetic inflammation. By the time Michio Suzuki his first loom built were brands like Zedel (NSU), Royal Enfield, Puch, Peugeot, Norton and Husqvarna all motorcycles in Europe to build just like Indian and Harley-Davidson in America. Motorcycle magazines have already been issued and engine reliability rides organized clubs in Europe. The first TT race at the Isle of Man has been held in 1907.

Japan was without a doubt not a pioneer in the field of motorcycles. The Japanese manufacturers only came decades after the European manufacturers and in the beginning they were not copying Western designs and techniques. Until years after the second world war the mighty Japanese manufacturers dominate the world market.

Back to the time before the second world war. Suzuki Loom Manufacturing Company is an impressive company, but there is still little demand for its products. Suzuki is considering in the automotive industry. 20000 cars in Japan are imported on an annual basis, which is insufficient to the ever growing demand for cheap means of transport can be met. Michio sees the hole in the market.

In 1938 builds Suzuki a first prototype for a car, based on the Austin Seven. The Suzuki has an Austin development team in England bought, taken apart and studied. A few month later they were able to make a replica of the English 737 cc car. Japan had little knowledge how a good car or motorcycle should be produced, imitation seemed therefore a good way to quickly get started.

|

(Foto: Austin Seven Saloon)

|

|

The moment turned out to be poorly planned. Japan was preparing for the war. The project was abandoned and the Suzuki variant of the Austin Seven never went into mass production. It would have been no original idea because also the first Nissan on an Austin Seven was based.

After the war follows a period of reconstruction and economic instability. The manufacture of looms was renewed but a wave of strikes in the 1940s and in the beginning of the 1950s, combined with the post war chaotic financial structure was almost the end of the Suzuki Loom manufacturing Company.

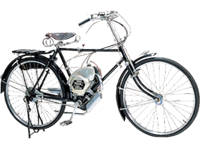

The story goes that the son of Michio Suzuki, Shunzo, the idea came to his bike to motorize on an autumn day on the way back from a day of fishing. For his own pleasure Shunzo went to the drawing board he had at home and started a bicycle auxiliary engine design. If the story is true or not, the production of auxiliary engines Suzuki saved from destruction.

In november 1951 the constructors of Suzuki Loom Manufacturing Comapny with designing a auxiliary engine for a bicycle. The idea is not unique, there were certainly 100 other Japanese companies with the same idea. For example, started in 1946, Soichiro Honda Technical Research Institute, where he overhauled small engines were used by the Japanese army in the war and edited this on cycling. A year later he produced already own engines. By the time Suzuki its first auxiliary engine in production took Honda already owned 70% of the market.

|

(Foto: 36cc "Power Free") |

|

Before the 36cc "Power Free" engine was introduced, still became a 30cc prototype named "Atom" built. This was however not in series production.

The Suzuki auxiliary engines quickly excelled by the high quality making them a great success were in Japan. Many of the original ideas by Shunzo Suzuki could be found in the final product. The engine consisted of a square 36X36 mm two-stroke with piston-controlled ports. The engine was in the bike frame placed directly above the pedals. The bike was powered by means of the normal bicycle chain and by applying special gears it was possible to freewheeling while the engine was running. The engine could be helped also by means of the pedals or completely disconnected from the motor.

The system was so ingenious that the patent office of the new democratic Government granted Suzuki grant to continue research into the development of motorcycles. Unlike many competitors used Suzuki for the "Power Free" own built engines and no remaining engines of the army or engines built under licence by other manufacturers. Suzuki produced all parts of the engine itself, so also the carburetor and the ignition coil.

|

(foto: 58cc Diamond Free 1953) |

The "Power Free", which was introduced at the end of 1951 was only a few months on sale, before he has improved dramatically. Just after the introduction of the "Power Free" modified the Japanese Government the requirements to a small motorcycle. A driver's license was no longer needed for a motorcycle with a 4 stroke engine to 90 cc or a 2 stroke engine to 60 cc. Suzuki started immediately with the development of an engine with an increased capacity to 60 cc and a 2 speed gearbox.

In 1953, a new model, the "Diamond Free" introduced. This model was built to the same design principles as the "Power Free" and made use of the same transmission methods. The engine was 58CC (43 mm X 40 mm) with a power output of 2 HP at 4000 rpm and equipped with neat aluminum end caps.

THE FIRST SUZUKI CARS

Already in the thirties of the 20th century, Suzuki plans to expand production to cars. In 1937, as part of a feasibility study, an Austin Seven from England, taken apart and examined. In the autumn of 1937 was a prototype of a motor and gearbox ready after which it was decided to produce a number of prototypes of the car. These prototypes were fitted with a water cooled 750 cc side valve engine light metal combined with a gearbox with 4 gears. Unfortunately, the project had to be stopped when the war broke out between Japan and China.

In January 1954 the plans were to build a car again only from the refrigerator. The other time also meant that the plans had to be changed drastically. Suzuki had to start over and took out 3 cars from Europe to study: a Volkswagen Beetle, a Lloyd and a lemon. All three cars were taken apart and studied.

This time is the beginning of the Japanese mini cars. The Japanese Government decided to provide tax benefits for small cars with small engines to lighten the load of the road network, as much as possible, to limit. By the begun mass motorization threatened the road network about to be taxed. This is the beginning of the Japanese K (Kei) class car.

With the goal of the mini car for eyes started the Suzuki engineers to compare the three cars:

- front engine with front wheel drive

- front engine with rear-wheel drive

- rear engine with rear-wheel drive

|

(Foto: Suzulight 360 SS) |

|

|

|

(Foto: Lloyd LP600) |

After weighing the advantages and disadvantages of each layout was eventually decided that a motor in the front with front wheel drive would have the best opportunities. On August 25, 1954 was a first chassis, in the form of a backbone chassis with Central tube, and an engine available for a test. In this way could easily be tried out a number of design details such as the suspension and the steering mechanism. After completion of the test program got the car a bodywork that was designed by Michio Suzuki and clear agreements with the Lloyd. Thus the "Suzulight SS Sedan" was born of which the first copy Middle 1955 was completed after the Japanese Government's permission was obtained to begin the production. Meanwhile, thought about a successor to the car with a better design, lower weight but with the same comfort for the passengers and an equally large load capacity. Soon it was added by making a small adjustment to the back of the car, two variants of the car: the "Suzulight SL" mini order and the "Suzulight SP" mini pick up. Production began in October 1955 3 to 4 Suzulights per month and already in February 1956 was the production grown to 30 cars per month.

All three models were competitively priced to the competition from companies like Mistubishi, Toyo Kogyo, Daihatsu and Fuji Heavy Industries that came on the market at the same time. A change in legislation allowing 15% excise tax on passenger cars levied was made sure that the production of the SS was stopped. By after buying 2 extra chairs in the SL to post the luxury tax could easily be circumvented. Because the loading weight of the SL was more favorable than the SP's pick up was also simultaneously decided to stop the production of the SP.

In July 1959 the Suzulight SL succeeded by the Suzulight TL. Seemed the bodywork of the SS and SL strongly on the Lloyd who had modeled for this car, so did the TL strongly reminiscent of the British Mini. The weight is dropped from 520 to 490 kg, the wheels are shrunk from 16 "up to 12" and the car has 4 seats whose rear seats foldable to the entire floor with a maximum load capacity of 300 kg. This model is produced unchanged until February 1963 and retrieves sales numbers of 200 pieces per month.

During that period are subcutaneous all kinds of improvements. The main bearings and big-end bearings be increased to guarantee longer life and from October 1961 is the gearbox with 3 ongesynchroniseerde gears replaced by 4 fully synchronized gears. In the meantime also been working on a full-fledged persons executed by the TL. In March 1962, this implementation on the market as the Suzulight TLA.

From marketing research showed that the Japanese market had to need a lightweight truck to 3 requirements should be met:

- a large load floor that should be easy to be loaded

- sufficiently robust for general commercial use

- low price combined with low cost of ownership

|

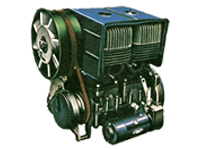

(foto: 1959 Suzuki Suzulight engine) |

The Suzuki design team went with these requirements to get started and in 1961, the Suzuki Carry FB introduced. The short front cabin offered only to the driver and a passenger. The engine stood under the seats and consisted of a very compact 2 cylinder engine with 21 HP at 5500 RPM. The cargo floor mat 1.5 square meters. With a retail price 295,000 yen, a price that is significantly below that of the competition was, it turned out the Carry FB a hit. It soon became an export version, the Carry FBL built and in 1964 the Carry FBK. Because the market had to a close order also requires implementation of the truck was in 1962 the Carry FBB, a performance specially for the Japanese post and telecommunications and the Carry FBC for general commercial use on the market. At the end of that year was also a four-person implementation on that 4 people and 200 kg loading weight should carry.

In 1963, the production of the Suzulight TL order stopped. The car was replaced by the Suzulight FE system. The FE had a new nearly square 2 cylinder engine with a bore of 61 mm and a stroke of 61, 5 mm with improved performance and a new lubrication system that mixing two stroke oil made redundant by the gasoline. By adjustments to the back of the car got the car a larger load capacity and a larger back door to the loading of the car easier. For the rear passengers was a folding rear seat. A few month later became also the persons executed, the Suzulight TLA replaced by the Suzulight FEA. With the introduction of the FEA was also the braking system. To the front wheels larger brake drums to assemble than behind a better balance was obtained. By the excellent performance of the new engine obtained the Suzulight FEA the first, second and fourth place in the mini class of the Japanese Grand Prix race in 1963.

The base for the SC 100 was the introduction of the Fronte 800 C10.

The Japanese counterpart in Europe so popular GT-Type.

The liquid-cooled three-cylinder two-stroke block of 785 cm3 yield as much power as an average 1000 cm3 block.

However, this sedan was not the weapon that Suzuki wanted to enter the battle for the buyer's favor.

Before that, another model chosen: the Fronte LC10.

SUZUKI FRONTE LC10

In April 1967 Suzuki led Japan into a real huge publicity offensive in which each possible medium was used.

The entire sales staff was even re-trained to be able to switch from selling primarily commercial vehicles to passenger cars.

With the slogan & ldquo;A sports sedan that makes driving fun again” The LC10 was introduced on the market.

The result exceeded all expectations.

Before the end of the year, 7,000 units per month built.

One of the most famous stunts Suzuki was 500 LC10 cars for a week long were just loaned to members of the public.

Thus sloppy 170 000 fans came to sign to serve as a test driver!

The round shaped Fronte in Japan has the nickname "Daruma", a Japanese roly-poly doll.

It is the smallest and only Keicar car which is inspired by fashionable at the time Coke-bottle shape.

LC50

In 1969 Suzuki importer Nimag brings together for the first time a Suzuki to the Netherlands.

About 50 of these Frontes are sold through a modest (Toyota) dealer network.

In 1969, the Fronte gets a facelift and brings an export model of the LC50.

The LC50 is based on the LC10 luxurious version but has a 475cc engine with 29SAE hp.

The LC50 is supposedly built only 1,000 units of which were sold by the importer 200 units in the Netherlands.

SUZUKI FRONTE LC10 SS

To meet the relentless demand to meet increased power, was already released the Fronte LC 10 SS in November 1968, with a water-cooled three-cylinder and sporty accessories as a tachometer, racing bucket seats and mirrors.

The result was a top speed of 115 kilometers per hour.

It was also the first car in its class that could take the sprint over 400 meters in less than 20 seconds.

The SS 360 with 36 hp, will be succeeded by the SSS in April 1970.

STIRLING MOSS

For the LC 10 SS knew Suzuki perfectly to get the publicity, by the famous British racing driver Stirling Moss, together with the Japanese racing legend Mitsuo Itoh to make a promotional tour in Italy!

The trip from Milan to Rome to Naples provided the necessary attention.

Italy was to Stirling Moss since the Mille Miglia of 1955 no unknown territory.

Later Mitsuo Itoh Suzuki's become the team leader of the motorcycle racing team and many grand prix to put his name.

SUZUKI FRONTE LC10 W

Backed by the success of Suzuki LC10 contracted the famous Italian designer Giugiaro.

He would still go for Suzuki shaping some models, including a brand new 2+2 coupé: Fronte Coupé GX (LC10W) in September 1971.

This design has clearly Giugiaro’s style elements that can also be found in the Lotus Elise and the Maseratie Merak.

Striking was still the placement of the 360cc 3-cylinder engine, which can be found in the back and was equipped with three-fold Mikuni 22mm carburetors.

Modern developments such as disc brakes, a folding rear seat, a ‘third door’ and radial tires all heard the standard specifications.

Depending on the type of assets amounted to 31,34 of 37pk.

SS-20 MK1

The production of the Fronte Coupe stopped in 1976 in modified form in 1977 as Suzuki Cervo SS20 to come back after being adjusted to fit the changed (fiscal) K class legislation.

For the domestic market was the engine size had grown to 3 cylinder 539 cm3 and 28 HP.

SS20 MK1 has strong resemblance to the earlier Fronte Coupe.

In particular, the schuinere forward and the rear window that can be opened now is different.

This is clearly visible as the two doors are side by side.

SS-20 MK2

The Suzuki Cervo Type 2 differs from the Fronte by the flat hood and a new front grille and bumpers other.

This version is the same as on the outside our SC-100-GX. Also the dash is exactly the same but the two-tone upholstery.

The Cervo appeared in three variants:

• CX as Cheap variant - Least luxury with only two clocks on the dashboard and cross-ply tires.

• CX-L as a luxury version - more focused on luxury with a wooden dashboard and two-tone white leatherette upholstery.

• GX-G as a sporting variant - similar in equipment with SC-100-GX.

SC100

For export (SC-100), Suzuki Cervo is for Europe to be fitted with a larger four-cylinder engine with a capacity of 970 cm3, accounting for an output of 47 hp.

More than enough to bring the light and sporting distinctive Suzuki looking for lively performance.

Had the Cervo on all models 10-inch wheels identical to the Austin Mini, but the SC-100-GX been fitted with 12 inch rims.

|

|

|

|

|

|

|

|